In advanced manufacturing, weight and performance go hand in hand. As industries demand materials that are lighter, stronger, and more sustainable, carbon fiber injection molding has become a leading technology. By combining carbon fiber reinforced plastic with precision molding, manufacturers can create high-strength carbon fiber parts that deliver both durability and design flexibility.

Modern manufacturers are increasingly adopting carbon fiber injection molding to achieve exceptional strength, lightweight performance, and aesthetic precision in a single component. This advanced process integrates carbon fiber materials with thermoplastics, producing parts that combine rigidity, durability, and refined surface finishes.

Hongbangyi Plastic, a specialist in carbon fiber injection molding, leverages high-performance carbon fiber reinforced polymer solutions and precision mold design to ensure superior fiber distribution, excellent bonding, and consistent dimensional accuracy.

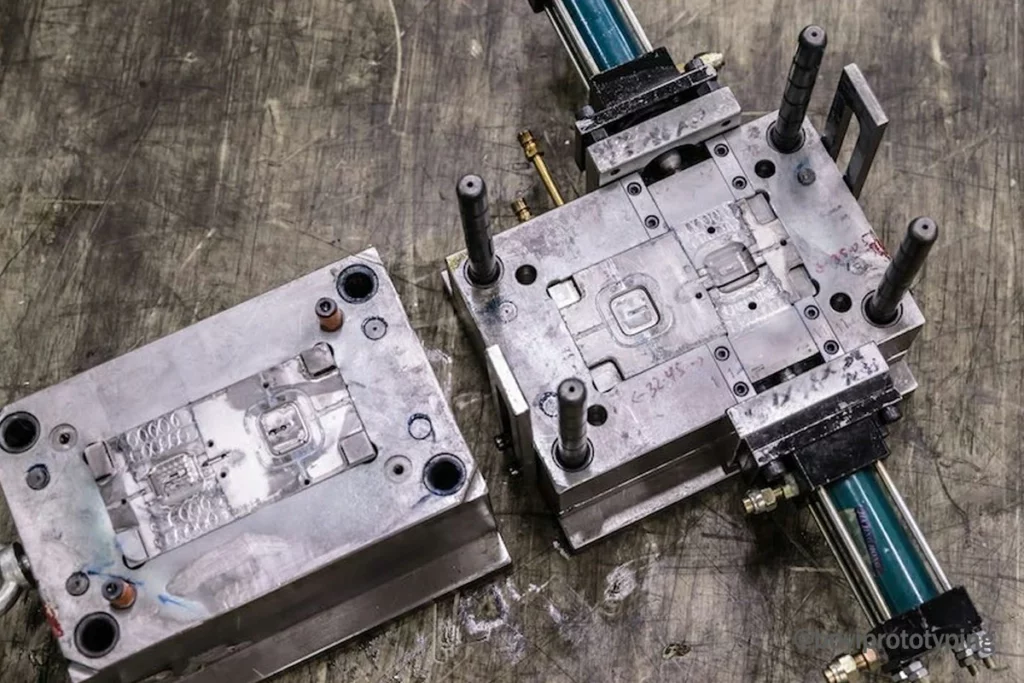

What Is Carbon Fiber Injection Molding?

Carbon fiber injection molding merges the benefits of carbon fiber composites with the speed of thermoplastic production. The process uses carbon fiber reinforced polymers, where chopped or continuous fibers are mixed into a carbon fiber resin matrix and injected into precision molds.

This method allows the creation of lightweight structural components that are as rigid as metals but much lighter — ideal for automotive carbon fiber parts, aerospace composite components, and high-performance consumer products.

How the Process Works

The carbon fiber injection molding process follows five main steps:

- Material Compounding – Short or long fibers are blended with thermoplastics like nylon (carbon fiber reinforced nylon), ABS, PP, or PEEK, forming uniform carbon fiber pellet compounding materials.

- Melting & Injection – The pellets are melted in acarbon fiber injection molding machine. Proper processing parameters for carbon fiber, such as temperature and pressure, ensure even fiber distribution and reduce fiber breakage during injection molding.

- Mold Filling – The molten mix fills the cavity. Fiber orientation control is critical here, influencing the final mechanical properties of carbon fiber plastics.

- Cooling & Solidification – Controlled mold temperature optimization and cooling rate in carbon fiber composites enhance dimensional stability in composites and surface finish.

- Ejection & Finishing – Once cooled, the part is released and may undergo polishing or coating for a refined carbon fiber surface finish.

Advanced factories use automated carbon fiber molding systems with real-time monitoring to maintain consistent quality and speed.

Key Advantages

1. Strength with Less Weight

Carbon fiber reinforced plastic offers an exceptional strength-to-weight ratio, up to five times stronger than steel but 70% lighter. These high-performance molded composites are ideal for performance-driven industries.

2. Dimensional Accuracy

The combination of mold flow simulation for carbon fiber and precise cooling ensures excellent dimensional stability in composites — crucial for tight-tolerance parts.

3. Superior Mechanical Performance

The aligned fiber structure improves tensile strength, stiffness, and impact resistance, making it perfect for structural plastic composites used in vehicles, aircraft, and industrial equipment.

4. Design Flexibility

Unlike traditional layup processes, carbon fiber composite molding supports complex geometries, thin walls, and intricate details while maintaining strength.

5. High-End Appearance

The unique weave pattern of carbon fiber surface finish gives products a premium aesthetic — often used in luxury electronics and sporting goods.

Common Materials Used

The base resin determines performance. Typical thermoplastic carbon fiber composites include:

- Carbon fiber reinforced nylon (PA6/PA66) – durable and chemical-resistant

- Carbon fiber reinforced PEEK – high-temperature aerospace-grade plastic

- Carbon fiber reinforced ABS – tough with a glossy finish for housings

- Carbon fiber reinforced PP – lightweight and economical

- PPS with carbon fiber – flame-resistant and stable

Each carbon fiber polymer blend is tailored to the environment — from automotive load-bearing parts to consumer product housings.

Design Considerations

Effective carbon fiber mold design is crucial to performance and consistency.

- Fiber Orientation Control: Gate and runner placement determine strength direction.

- Mold Temperature Optimization: Uniform temperature ensures smooth carbon fiber surface finish and prevents warpage.

- Injection Speed and Pressure: Balancing injection speed and fiber distribution prevents breakage and voids.

- Mold Flow Simulation: Predicts fiber orientation and mold cavity pressure control for better part quality.

- Tool Material: Because carbon fiber is abrasive, hardened molds are needed for durability.

Applications Across Industries

Automotive

Automakers rely on carbon fiber composite parts manufacturing to reduce weight and improve fuel or battery efficiency.

Typical components include brackets, seat frames, and under-hood covers — combining safety and performance.

Aerospace

Aircraft and drones use carbon fiber reinforced PEEK and PPS for aerospace composite components, including propellers, cabin panels, and mounts — achieving high heat resistance and stiffness.

Sports Equipment

Sports equipment composite molding produces strong, lightweight gear like bicycle frames, rackets, and helmets. The process allows consistent shapes and customized stiffness levels.

Consumer Electronics

Devices such as laptops, phones, and cameras use carbon fiber reinforced ABS for carbon fiber consumer product housings — stylish, durable, and heat-tolerant.

Industrial Automation

Robotics benefit from precision carbon fiber molding. Low-weight structural components improve efficiency and motion speed, supported by automated carbon fiber molding systems for mass production.

Challenges and Solutions

- Fiber Breakage During Injection Molding: Controlled shear and optimized processing parameters for carbon fiber preserve fiber length.

- Tool Wear: Carbon fiber’s abrasiveness requires robust tool steels and coatings.

- Cooling Rate Control: The cooling rate in carbon fiber composites affects internal stress and strength; balance is essential.

- Material Cost: Although costlier than standard plastics, CFRP’s performance justifies its use in critical parts.

Innovation and Sustainability

Modern R&D focuses on hybrid carbon fiber materials and sustainable lightweight materials.

- Recycled carbon fibers lower costs and waste.

- Bio-based resins replace petroleum polymers.

- Hybrid composites mix glass or natural fibers to optimize flexibility and price.

Combined with automated carbon fiber molding systems, these innovations make the process more efficient and eco-friendly.

Future Outlook

The future of carbon fiber reinforced plastic lies in smarter automation, real-time monitoring, and AI-driven optimization.

Upcoming trends include:

- Continuous fiber molding for ultra-strong components

- AI-enhanced mold flow simulation for carbon fiber

- Recycled and hybrid carbon fiber polymer blends for green manufacturing

As industries chase performance and sustainability, carbon fiber injection molding is becoming the go-to solution forhigh-performance molded composites — reshaping how modern products are designed and built.

Conclusion

Carbon fiber injection molding combines the speed of thermoplastics with the power of composites. Through precise fiber orientation control, advanced mold temperature optimization, and innovative automation, it produces lightweight structural components that deliver unmatched strength, precision, and beauty.

Whether for automotive carbon fiber parts, aerospace composite components, or consumer product housings, this technology defines the future of sustainable lightweight materials — enabling manufacturers to go lighter, faster, and stronger than ever.